Pneumatic or Hydraulic Needle Seal Shut-off Nozzle for Polymer Injection Molding

- Solve low viscosity polymer Leakage

- Shorten injection cycle time

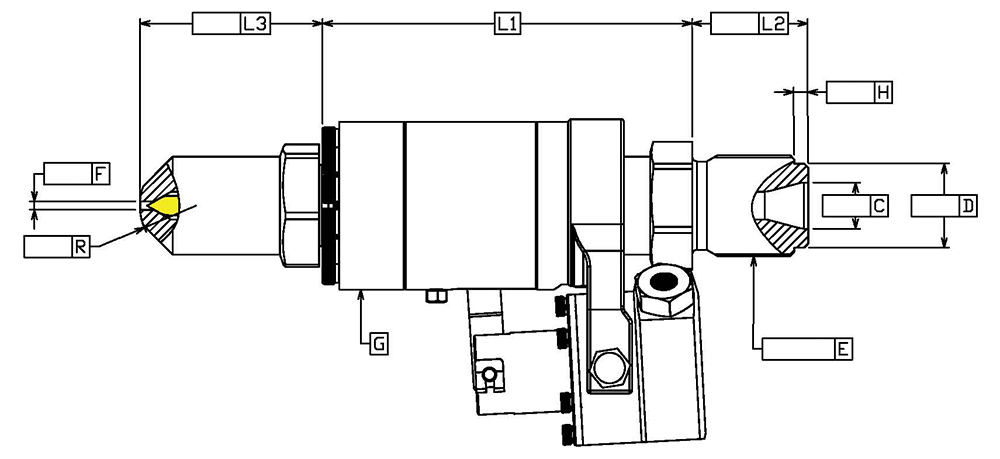

| PARAMETER | RN-I | RN-II | RN-III | ||||||||

| Max. Shot Weight (Ref.) | gram | 700 | 6000 | 30000 | |||||||

| Max. Screw Size (Ref.) | mm | 60 | 120 | 240 | |||||||

| Max. Machine Size (Ref.) | tonnage | 300T | 1200T | 3000T | |||||||

| Body Length (L1) | mm | 140 | 178 | 240 | |||||||

| Tip Length (L3) | mm | 20/63/93/113/Customized | |||||||||

| Heater Size (G) | mm | Φ60*80L | Φ80*100L | Φ115*150L | |||||||

| Air Pressure (Ref.) | Bar | 6 | 8 | 10 | |||||||

| Max. Inj. Pressure (Ref.) | Bar | 3000 | |||||||||

| Max. Temperature | °C | 400 | |||||||||

Needle shut-off nozzle can be optional by pneumatic or hydraulic drived, while it’s used a lot to prevent material leakage and wire-drawing of plastic, it can applied in synchronization dosing situation and also micro-foaming (physical or chemical) injection field.

Additional information

| Model | RN |

|---|---|

| Appliance | ThermoPlastic |

| Actuator | Pneumatic |

| Drive Pressure | 6-8Bar |

| Max. Injection Rate | 1600g/s |

| Max. Temp. | 450℃ |